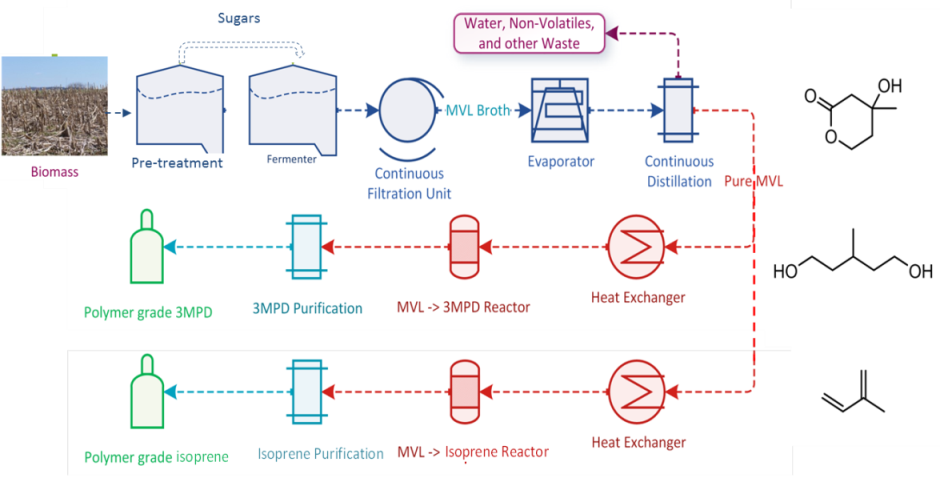

BioCatPolymers aims at demonstrating an integrated feedstock-flexible, economic and efficient technological route to convert low-cost, abundant and residual lignocellulosic biomass to high added value monomers that are converted to biopolymers via well-established manufacturing processes.

The novel approach proposed in BioCatPolymers surpasses the impediments of traditional solely bio-based approaches by combining efficient hydrolysis of lignocellulosic material to sugars which can be fermented with high yields to MVL, with highly efficient and selective thermochemical catalytic processes to the targeted products.